In this article, Leanne Beirne of BTP Architects offers insight into the complex design process behind the façade remediation works at The Exchange in Croydon. BTP have been working closely with us on the project, which involves replacing combustible aluminium cladding with a fully non-combustible alternative in line with current fire safety legislation.

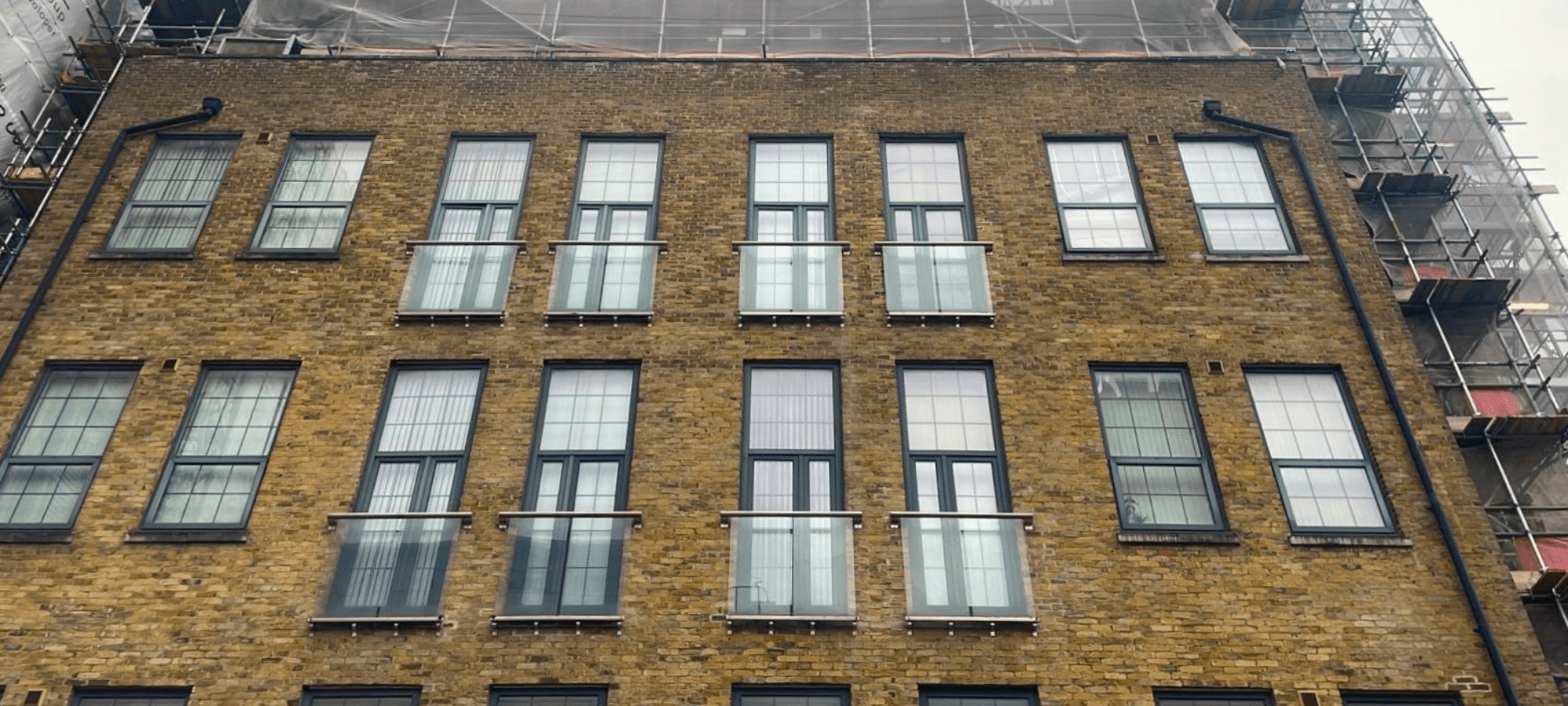

Urbanise approached BTP back in 2023 to provide detailed design drawings (RIBA Stage 4) of The Exchange in central Croydon. Originally built in the 1940s as the BT Exchange building, the building had been extended in the 1960s and later converted into apartments in the early 2000s with a penthouse suite constructed on the roof. The building was a mix of brickwork and aluminium cladding panels (Europanel), the latter of which is flammable and had to be removed and replaced with the latest non-combustible Europanel F5 system.

BTP were appointed by Urbanise initially to carry out a drawing package of “typical” details for each of the cladding types, such as window reveals, compartment wall and floor slab edges. At that point, the only opening up information available to us was the Fire Risk Assessment of the External Walls (FRAEW). The FRAEW showed a range of locations, and a detailed measure of the external wall build ups, but our experience on high-rise cladding remediation had taught us never to assume that a detail might be “typical”. That’s difficult to gauge until you’re able to strip back all the external walls.

The scope of what was “typical” expanded once the scaffold was up and the Urbanise team started to investigate the building through more extensive opening up. We found that the central courtyard in particular was a mash of three different eras of construction, with a 21st century steel structure and SFS filling in the gaps between 1960s concrete frame and 1940s brickwork. No two junctions were the same. Some of the walls had cavities greater than half a metre deep.

One of the biggest design challenges was figuring out a way to securely fix new cavity barriers to the existing structure. For the floor slab edges, that’s straightforward – the closed state cavity barriers specified are fire tested under BS EN 1363-1:2020 between concrete to concrete/masonry, so fixing these to concrete is the default. Fixing to different materials, such as plasterboard or steel, won’t necessarily work with the fire testing of a specific product, and need careful consideration.

Working with our Fire Engineer, Tony Bolder, we were able to come up with a design solution that allowed the cavity barriers to be securely fixed. We then adapted that solution to a variety of locations. Sometimes that meant having to specify a different cavity barrier product in a different location, so that we knew we were within the fire test parameters.

There’s also the difficulty of being able to reach around existing structure and the parts of the wall that aren’t being touched or removed to be able to fix the new cavity barriers securely. This is where collaboration with the Urbanise team – including Pops Facades and Longworth – was key.

In all, for the courtyard alone we produced 224 drawings. The works are currently progressing on site and the collaboration doesn’t stop there – we regularly visit site and help the Urbanise team to build in accordance with our designs. Having a main contractor like Urbanise, as well as contractors like Longworth and POPS, who aren’t afraid to ask questions and take their time with the answers, has meant the works are to a very high standard.

For an architect, this type of design work might not be one that’s visible when the works are finished, but there is immense satisfaction in knowing that we have helped to make a building safer for its occupants as a result of our problem solving and teamwork.